Only people can create the sharpness of the blade.

Only machines can grind accurately in units of 1/1000 mm.

The most important process in the sharpening of scissors, which is the final process for hairdressing scissors, is the "blade sharpening" by the craftsman.

It is an analogy of the craftsmanship inherited from the tradition of Seki's swordsmiths.

In order to allow our craftsmen to concentrate on the important blade sharpening process, which is practiced less often in modern days, we have introduced CNC machine tools for processing with an accuracy of 1/1000 mm.

The CNC machine tools play an important role in Japan's leading-edge manufacturing and are indispensable for automotive and aircraft parts that require particularly high processing accuracy.

Our strength is its unique manufacturing method that combines the "strength of craftsmen" that only craftsmen can do with the "strength of machines" that only machines can do.

We never forget to keep evolving.

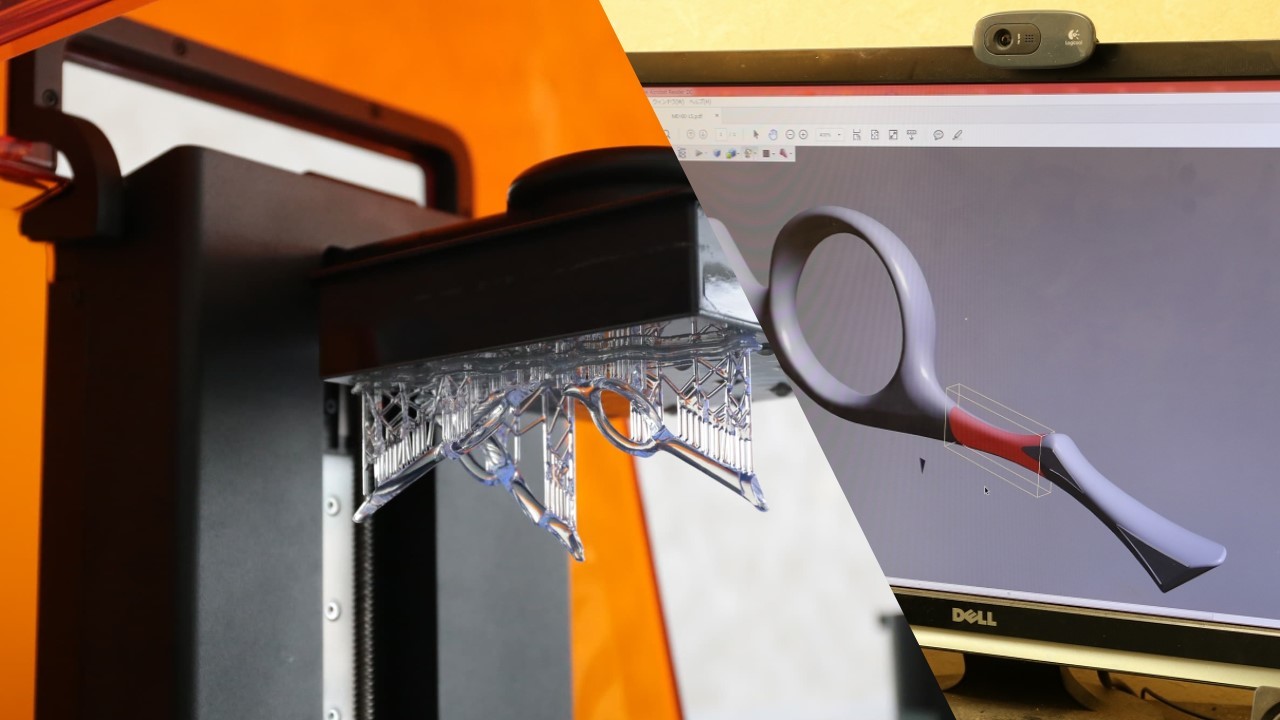

The blade cutting industry has seemed to be moving away from new technologies, but we are actively introducing the latest technologies to develop better products.

Prototypes of handles, which used to be hand-made, are now generated from 3D data on a 3D printer, enabling us to develop products quickly and efficiently.